- Mechanical

- Hydraulic

- Environmental

- Operational

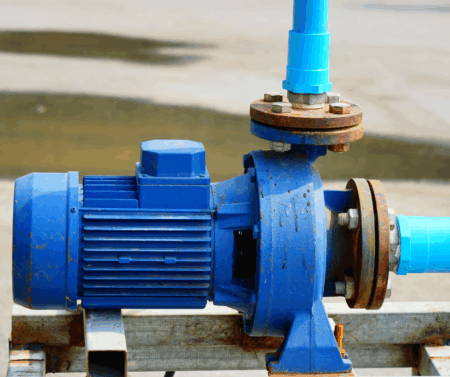

This blog will cover the four primary reasons why commercial pumps fail and how our team at Elite Pumps can help reduce your facility’s downtime by using preventative maintenance.

#1: Mechanical Pump Breakdown: Bearings and Lubrication

The biggest opportunity for a commercial pump to fail can be found in the internal components, such as the bearing and mechanicals. Damage to these components is often traced back to a single problem – lubrication gaps. This is because the bearings that require lubrication play a huge role in supporting the pump’s operation, both the shaft of the pump and under both radial and axial loads. Poor lubrication of these vital parts accounts for up to 80% of bearing failures, making supporting them through proactive maintenance integral.

Improper lubrication can lead to loads of metal-on-metal contact and excessive friction. This friction quickly turns into heat generation; in a matter of minutes, this heat can contribute to thermal expansion and softening of the bearing’s steel. Over time, if the unit is not lubricated, it can cause accelerated wear and pitting on the outside of the part.

Can Commercial Pumps Be Overlubricated?

Additionally, the correct amount of lubrication is essential for keeping your commercial pumps in good condition and preventing costly downtime. Sometimes, overlubricating can act like a trash collector within the unit. Over time, it can begin collecting water, dirt, other fluids, or debris, all of which contaminate the lubrication. When the lubricant becomes contaminated, this can lead to a slew of serious issues for your commercial pump, including:

- Rust

- Corrosion

- Etching

- Premature failure

Finally, overlubricating your commercial pump can also lead to the lubricant heating up too fast, causing the same issue as underlubricating your pump.

#2: Commercial Pump Hydraulic Stress and Misapplication

In many cases, expensive downtime isn’t caused by friction and underlubrication alone. Oftentimes, the biggest issue your commercial pump is facing is the fluid itself or the environment it is working in. When your commercial pump is under hydraulic stress, the outcomes can be devastating for your operation, costing you thousands in full-scale repairs due to long-term destruction caused by cavitation

Cavitation is what happens when a commercial pump is used outside of its specified limitations. This most often happens due to the pressure in the pump inlet dropping below the liquid’s unique vapor pressure, which makes vapor bubbles begin to form within the pump. Once the vapor bubbles continue to move into high-pressure zones, they implode – leading to shockwaves that pit the impeller and casing.

This is most often caused by three primary reasons:

- The suction lift is too high

- Suction piping is too restrictive, which could also include clogged strainers

- The fluid’s temperature within the pump is too high

#3: Improper Pump Environment and Material Incompatibility

While mechanical failure is a slow process that oftentimes is noticed once it is too late, an incompatible pump material causes a faster, more random attack on your system. When the fluid a pump is moving is completely incompatible with the metal of the commercial pump, failure is just around the corner, regardless of the size or power of the unit.

This is because of the chemical corrosion that can occur during the pumping process; for example, this is extremely common for standard cast iron pumps that are being used for acidic materials, as the fluid will quickly eat away at the unprotected metal material and render it completely unreliable. This process is expedited by extremely fast pump flow rates, as the sheer volume of corrosive fluid can cause even greater damage in a much smaller amount of time.

The problem with this is that over time, corrosion changes the hydraulic geometry and shape of the pump. This often causes wider openings that completely restructure how fast your fluid is being pumped throughout the building, potentially causing harmful outcomes, including:

- Loss of efficiency

- Increased energy consumption

- Unbalanced impellers that cause jostling and mechanical failure in the long run

#4: Electrical Or External Pump Failures

Even if you manage to solve every internal or hydraulic issue that your commercial pump is facing, it may still be vulnerable to unideal conditions in its external environment. While these threats may seem less prevalent than their internal counterparts, they can cause significant downtime and require professional help from your team at Elite Pumps.

The biggest external issue with commercial pumps is often electrical, caused by power supply issues such as phase imbalances or incompatible voltage. These imbalances can cause significant temperature rises in the motor windings, which, over time, can cause insulation failure and complete commercial pump burnout. Additionally, improper voltage can cause excessive currents or be drawn in order to maintain power, contributing to large-scale overheating and damage.

As for the conditions of the pumps’ external environment, the biggest issue is typically in the piping. When pipes are poorly supported, they rely on the pump casing to align them – putting all the weight on the pump casing and leading to poor function. This can cause distortion of your unit and misalignment of both the shaft and the motor after the startup. Excessive weight can also contribute to mechanical failure due to overworking the seals and bearings.

The best warning signs to watch for include vibrations and odd, abnormal noises coming from the commercial pump. Additionally, feeling heat radiating off the unit is also a clear indication that something is wrong, and a full-fledged shutdown could be around the corner if not quickly addressed.

How We Provide Predictive Commercial Pump Reliability

The biggest impact on your Houston business’s bottom line is relying on predictive commercial pump maintenance to keep these four categories of failures from causing severe downtime. Knowing why a pump fails is invaluable, but the truth is that commercial pumps are delicate and require professional and highly skilled technicians to provide accurate care and maintenance. At Elite Pumps in Houston, our technicians know pumps and what makes them run well for years to come. Not only do we help our clients find pumps that work for their unique needs, but we also have years of expert knowledge into why they may fail due to misuse or unavoidable environmental concerns.

If you want to set your company up for financial success, the first thing you need to do is take control of expensive, unproductive downtime by investing in top-tier commercial pump care. Don’t let a failed pump lead to budget overruns, hazardous facility conditions, or long-term production pauses. Contact Elite Pumps today for a free estimate for commercial pump repair or a replacement estimate for your Houston business.